How Billet Size Variations Affect Clamp Design & Pricing

How Billet Size Variations Affect Clamp Design and Pricing

Introduction

Handling billets efficiently is a daily challenge in steel mills, rolling workshops, and billet storage yards. These heavy, often hot steel pieces need to be lifted and moved safely, quickly, and without damage to the material or equipment. That’s where clamp cranes and specialized billet clamps become essential tools.

Clamp design is more than just matching a weight capacity. It involves ensuring the clamp grips billets securely, accommodates variations in size and shape, and withstands environmental and operational conditions. If the clamp doesn’t match the billets, it can slip, damage material, or even cause downtime in your workshop.

Understanding how billet size affects clamp design is crucial for buyers and plant engineers. It directly impacts safety, operational efficiency, and long-term maintenance costs.

- Clamp design directly affects operational safety and handling efficiency.

Even small differences between the clamp and billet dimensions can create instability during lifting, increasing the risk of accidents or product damage. - Using the wrong clamp for varying billet sizes can cause crane wear, uneven load distribution, and higher maintenance costs.

A clamp that doesn’t fit properly can transmit uneven forces to the hoist, trolley, and runway rails, leading to faster wear and unexpected downtime. - Proper clamp selection balances cost, performance, and safety.

While adjustable or customized clamps may cost more upfront, they save money over time by reducing maintenance needs, downtime, and potential material losses.

Billet Sizes

Billets are rarely perfectly uniform. Even within the same production batch, there can be differences in length, width, height, and surface conditions. Recognizing these variations is essential when selecting or designing the right clamp for your overhead crane, gantry crane, or hoist system.

Typical Billet Dimensions and Tolerances

Before selecting a clamp, you need to know the standard sizes and tolerances of the billets handled in your workshop. Different steel plants produce billets with different dimensions depending on rolling processes and intended applications.

- Square billets: Usually 100×100 mm, 120×120 mm, 130×130 mm, 150×150 mm, 160×160 mm, or 180×180 mm.

- Rectangular billets: Typical sizes include 120×150 mm, 130×180 mm, 140×200 mm, or 150×200 mm.

- Length: Most billets range from 3 meters to 6 meters; longer billets can reach 12 meters for certain applications.

- Tolerance: Width and height variations are usually ±5 mm to ±10 mm depending on the mill and rolling process.

Even small variations in dimensions can affect the clamping force needed and the jaw opening required, which is why clamps often need to be adjustable.

Differences Between Hot and Cold Billets

The temperature of the billet significantly affects clamp performance and durability.

- Hot billets: Typically handled immediately after rolling at temperatures between 1000–1200°C. They expand slightly due to heat, are softer, and more prone to surface damage. Clamps for hot billets often need heat-resistant materials and coatings.

- Cold billets: Usually stored or processed at room temperature. They are harder, may have burrs or scale, and require clamps with more rigid gripping surfaces to avoid slipping.

Selecting a clamp that matches the billet's temperature and material hardness is essential to prevent jaw wear, deformation, or slippage.

Impact of Irregular Shapes, Chamfers, or Surface Conditions

Not all billets are perfectly square or smooth. Irregularities can create challenges for clamp gripping.

- Chamfered or rounded edges: Many billets have slightly chamfered corners from rolling, which reduces gripping surface area and may require specialized jaw shapes.

- Surface roughness or scale: Rust, scale, or oily surfaces can reduce friction, meaning clamps need stronger force or gripping teeth to prevent slipping.

- Twisted or warped billets: Occasionally, billets may have minor twisting or bending, requiring clamps with adjustable or flexible jaws.

Key Practical Takeaways for Buyers

- Measure billets accurately, including length, width, height, and corner conditions.

- Identify the frequency and range of size variations in your operations.

- Match clamps to billet temperature, surface condition, and shape for safe and efficient handling.

Clamp Design Considerations for Different Billet Sizes

Choosing the right clamp is not just about lifting capacity. Billet handling requires clamps that match the dimensions, weight, and surface condition of the steel pieces, while ensuring safety and operational efficiency. The size variations of billets, from square to rectangular, hot to cold, and small to large, strongly influence clamp design.

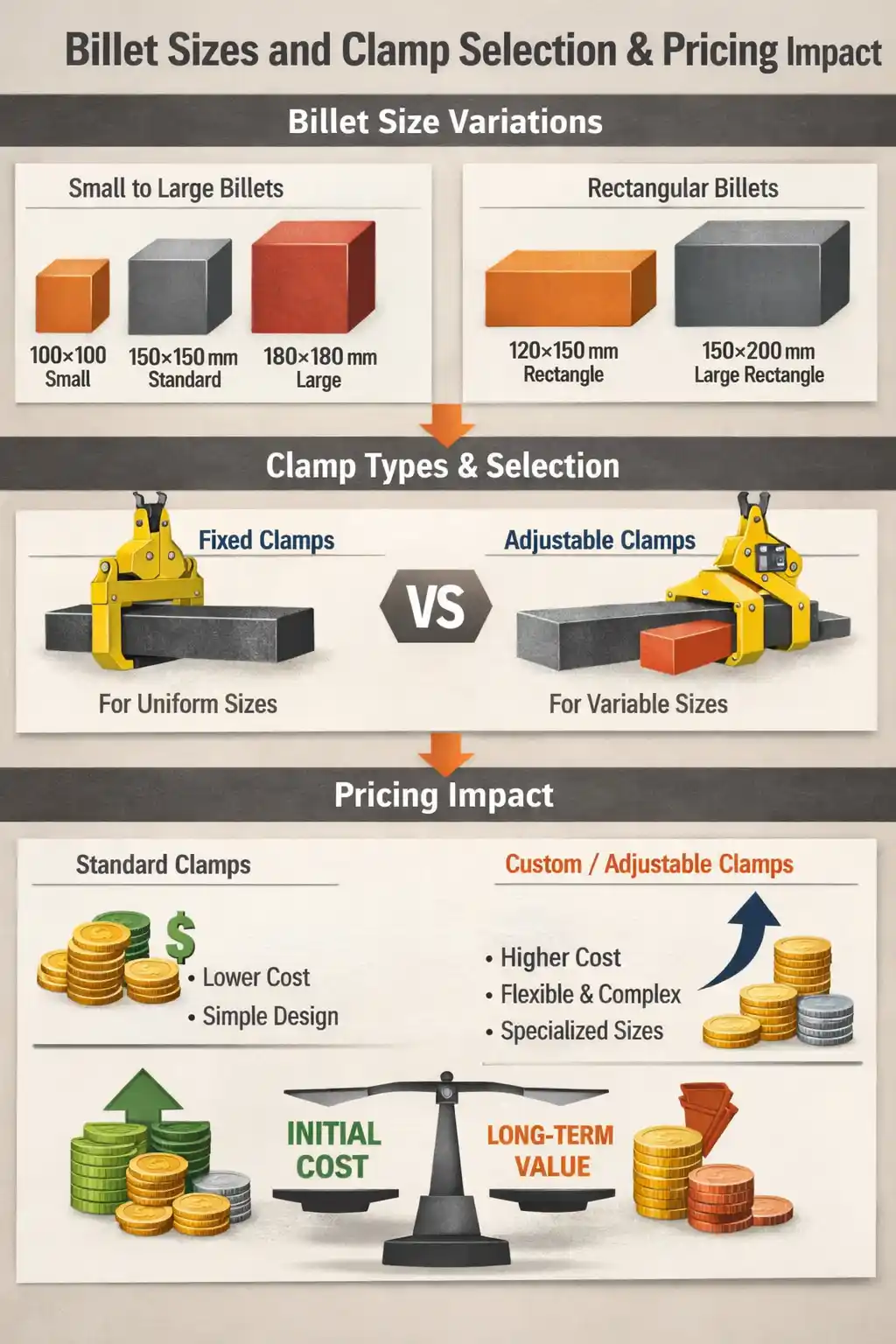

Adjustable vs. Fixed Clamps

Workshops handling billets may face a range of sizes. Some plants work mainly with uniform billets, while others need to move multiple sizes frequently. Selecting the right clamp type can save money and reduce operational issues.

- Adjustable clamps: Handle a range of billet sizes, ideal for billets varying from 100–180 mm square or 120×150–150×200 mm rectangular. Reduces need for multiple clamps and downtime.

- Fixed clamps: Designed for specific billet sizes like 130×130 mm or 140×200 mm. Simpler, more durable, lower upfront cost, but less flexible.

- Buyer tip: For frequent size variations, adjustable clamps provide better long-term value. For uniform billets, fixed clamps are reliable and economical.

Jaw Opening and Clamping Force

The jaw opening and clamping force determine whether a clamp can securely hold billets without slipping or causing surface damage. Billet size, shape, and surface conditions all impact these requirements.

- Jaw opening: Must accommodate the largest billet while gripping smaller ones securely. Example: 100–200 mm for square, 120–200 mm for rectangular billets. Adjustable jaws help with size and edge variations.

- Clamping force: Depends on billet weight, surface friction, and temperature. Hot billets (softer, 1000–1200°C) need gentler grips; cold billets (harder) require stronger force.

- Practical advice: Follow manufacturer specifications for jaw opening and clamping force to ensure safety and clamp longevity.

Material and Wear Resistance

Billet hardness, temperature, and surface condition affect clamp wear. Selecting the right material and coatings can extend the life of the clamp and protect billets.

- Clamp body material: High-strength alloy steel, heat-treated steel for frequent handling of hard billets.

- Jaw lining/coatings: Rubber, polyurethane, or heat-resistant metals improve grip, reduce wear, and protect billet surfaces.

- Temperature considerations: Hot billets at 1000–1200°C may soften standard clamps; heat-resistant coatings or alloy jaws recommended.

Special Features

Modern clamps often include features to improve safety, reduce downtime, and make handling billets easier, particularly in high-temperature or heavy-duty operations.

- Safety locks: Prevent accidental opening during lifting, essential for long or heavy billets (6–12 meters).

- Overload protection: Prevents lifting beyond rated capacity, protecting the clamp and crane.

- Heat-resistant coatings: Needed for hot billets to prevent jaw deformation and reduce wear.

- Adjustable alignment: Useful for twisted or irregular billets, ensuring even load distribution.

Buyer recommendation: Evaluate these features based on billet dimensions, temperature, and workshop environment to reduce accidents, material damage, and downtime.

Impact on Crane Performance

The size and weight of billets, combined with clamp design, have a direct effect on how your crane operates. Even a well-designed clamp can't fully compensate if the crane itself isn't properly matched to the loads. Understanding these factors helps buyers make decisions that reduce wear, improve safety, and prevent costly downtime.

Load Distribution and Crane Stability

How the billet's weight is distributed through the clamp affects the crane's stability during lifting and transport. Uneven gripping or oversized billets can create imbalance, putting stress on the crane structure.

- Even load distribution: Properly sized clamps matched to the billet dimensions ensure the load is balanced across the hoist and trolley. For example, a 150×150 mm billet weighing 1.5 tons needs even gripping along its length to avoid tilting.

- Irregular billets: Twisted or chamfered billets may shift during lifting if clamps are not adjustable, causing instability.

- Practical tip: Buyers should consider clamps with adjustable jaws and alignment features when handling billets with size variations from 100×100 mm to 180×180 mm, or rectangular billets up to 150×200 mm.

Increased Wear on Crane Hoists and Trolleys

Oversized or irregular billets can create uneven forces on the crane hoist and trolley, accelerating wear and potentially shortening the equipment's service life.

- Heavy or long billets: Lifting a 6-meter billet that is 180×180 mm square or 150×200 mm rectangular requires careful force distribution to avoid overloading a single hoist wheel.

- Irregular surfaces: Chamfers, burrs, or twisted billets increase friction and stress on the trolley and hoist components.

- Practical advice: Buyers should ensure that crane hoists, trolleys, and wire ropes are rated not just for the maximum weight, but also for the dynamic effects of uneven or shifting loads.

Considerations for Crane Runway and Rail Loads

The crane runway and rails must support both the static and dynamic loads of the crane, clamps, and billets. Billet size directly affects these calculations.

- Larger billets: A 6-meter-long, 180×180 mm billet handled frequently can significantly increase rail wear and load on runway beams.

- Dynamic forces: Sudden starts, stops, or uneven gripping can cause spikes in rail and beam loads, increasing maintenance needs.

- Practical recommendation: Buyers should consult structural engineers or suppliers to ensure the runway design accommodates the largest and heaviest billets, including load variations caused by irregular shapes or size differences. Proper runway design prevents bending, misalignment, and long-term operational problems.

Key Takeaways for Buyers

- Always match clamp type, crane capacity, and runway design to billet dimensions and weight.

- Consider dynamic load effects for oversized or irregular billets.

- Plan preventive maintenance for cranes handling frequent size variations to reduce wear and avoid unexpected downtime.

Pricing Implications

When it comes to clamp selection for handling billets, cost is always a key factor—but it's not just the initial purchase price that matters. The design, adjustability, and durability of the clamp all influence long-term expenses, maintenance requirements, and operational efficiency. Buyers need to consider both upfront costs and the total cost of ownership over the life of the crane system.

Cost Differences Between Standard vs. Customized Clamps

The type of clamp you choose will significantly affect your budget. Standard clamps are designed for common billet sizes, while customized clamps are tailored to handle specific dimensions, shapes, or special conditions.

- Standard clamps: Typically designed for common billet sizes such as 120×120 mm, 150×150 mm, or rectangular billets like 120×150 mm. They are generally lower in cost and suitable for plants handling uniform billets.

- Customized clamps: Designed for unusual sizes, long billets (up to 12 meters), oversized square billets (up to 180×180 mm), or irregular shapes. These clamps cost more upfront because they require special engineering, materials, or adjustable mechanisms.

- Practical advice: If your operation handles multiple billet sizes or unusual dimensions frequently, investing in a customized or adjustable clamp can reduce long-term operational issues despite the higher initial cost.

Effect of Adjustable or Multi-Purpose Clamps on Manufacturing and Maintenance Costs

Clamps that adjust to different billet sizes or shapes add flexibility, but they come with additional manufacturing and maintenance considerations.

- Manufacturing complexity: Adjustable clamps require precision machining, movable jaws, and sometimes special coatings to handle both hot and cold billets safely, increasing production costs.

- Maintenance requirements: More moving parts mean more regular inspections, lubrication, and potential replacement of worn components. Adjustable clamps handling billets from 100×100 mm to 180×180 mm may need frequent jaw alignment checks.

- Operational benefit: Despite higher maintenance, adjustable clamps reduce the need to purchase multiple clamps for different billet sizes, saving space and simplifying handling operations.

Long-Term ROI: Maintenance, Downtime, and Operational Efficiency

The real value of your clamp selection lies in long-term performance and cost savings. Cheaper clamps may seem attractive upfront but could lead to higher expenses later due to maintenance, downtime, or billet damage.

- Maintenance costs: Using clamps suited to your billet sizes reduces wear on jaws, hoists, and trolleys, lowering repair and replacement costs over time.

- Downtime reduction: Properly sized clamps minimize slippage and accidents, keeping production lines running smoothly and safely.

- Operational efficiency: Flexible clamps allow quick changeover between different billet sizes, improving throughput and reducing handling delays.

- Buyer tip: Calculate ROI not just by initial clamp price, but by considering savings from fewer replacements, reduced downtime, and improved operational efficiency. For workshops handling diverse billets—from 100×100 mm to 180×180 mm, or 120×150 mm rectangular billets—this ensures smarter investment.

Buyer Considerations and Decision-Making

Selecting the right clamp for billet handling is more than a technical decision—it's a strategic one. Buyers need to evaluate how clamp flexibility, billet size variations, and operational requirements intersect with budget and safety considerations. Making informed choices upfront can save significant costs and prevent operational problems down the line.

Evaluating Required Clamp Flexibility Based on Billet Size Range

Not all workshops handle billets of the same dimensions. Understanding the full range of billet sizes is critical to determine whether you need adjustable or fixed clamps.

- Billet size range: Consider the smallest and largest billets handled, for example, square billets from 100×100 mm to 180×180 mm, or rectangular billets from 120×150 mm to 150×200 mm.

- Flexibility needs: If your operation frequently switches between different sizes, adjustable or multi-purpose clamps reduce downtime and the need to maintain multiple fixed clamps.

- Practical tip: Map out the range of billet sizes handled monthly or weekly. This will clarify whether adjustable clamps provide a better long-term solution for efficiency and safety.

Assessing Frequency of Size Changes in Operations

How often billets of different dimensions are handled directly impacts clamp selection. Frequent size changes require more versatile equipment, while uniform operations may benefit from simpler, fixed clamps.

- High-frequency size changes: Workshops handling billets of various lengths (3–12 meters) and widths (100–180 mm) should prioritize adjustable clamps or modular clamp systems.

- Low-frequency size changes: Operations with mostly uniform billets, such as standard 150×150 mm square billets, can optimize cost by using fixed clamps.

- Buyer insight: Understanding workflow patterns and production schedules ensures the chosen clamp aligns with real operational needs and avoids over-engineering.

Balancing Upfront Cost vs. Operational Safety and Efficiency

Clamp selection is not just about initial purchase price. Safety, long-term maintenance, and operational efficiency must be considered.

- Upfront cost: Fixed clamps are usually cheaper, while adjustable or customized clamps may cost more due to added engineering and materials.

- Operational safety: Properly sized clamps reduce the risk of slippage, material damage, and accidents, which can be costly in both human and material terms.

- Efficiency and ROI: Investing in clamps that match your billet size range and handling frequency improves productivity, reduces downtime, and minimizes maintenance costs over time.

- Practical recommendation: Buyers should weigh the cost against expected operational savings and risk reduction, especially when handling billets of varying sizes—from small 100×100 mm billets to large 180×180 mm or long 12-meter billets.

Case Examples

Understanding theory is important, but real-world examples make it clear why billet size variations matter when selecting clamps. These examples highlight practical challenges, the impact on cost, and lessons buyers can apply to their own operations.

Example 1: Handling Mixed Square and Rectangular Billets

A steel workshop in Southeast Asia regularly handled square billets of 150×150 mm and rectangular billets of 120×150 mm. Initially, the plant used fixed clamps designed for the square billets.

- Problem encountered: When handling rectangular billets, the clamps could not grip properly, leading to frequent slippage, minor material damage, and additional downtime.

- Solution implemented: The plant invested in adjustable clamps capable of handling both square and rectangular billets within the 120–150 mm width range.

- Outcome: Production efficiency improved, incidents of slippage were eliminated, and long-term maintenance costs for hoists and trolleys decreased.

Lesson learned: Adjustable clamps provide flexibility for workshops handling multiple billet sizes, reducing operational risks and improving ROI.

Example 2: Long Hot Billets

A rolling mill in the Middle East frequently lifted hot billets 6 meters long, measuring 180×180 mm. The clamps were initially designed for standard 150×150 mm billets.

- Problem encountered: The oversized billets caused uneven gripping, increasing stress on the crane hoist and trolley. Jaw surfaces wore quickly due to higher clamping forces, and frequent adjustments were required.

- Solution implemented: The mill upgraded to clamps with extended jaw openings, heat-resistant coatings, and overload protection mechanisms.

- Outcome: The crane operated more smoothly, clamp wear was reduced, and operator safety improved. The investment also prevented expensive crane downtime.

Lesson learned: Oversized or long billets require clamps specifically designed for the dimensions and temperature, including heat-resistant materials and safety features.

Example 3: Irregular or Twisted Billets

A European billet storage yard occasionally received billets with slight twists or chamfered edges, ranging from 100×100 mm to 180×180 mm. Fixed clamps often failed to grip securely, creating imbalance during lifting.

- Problem encountered: Slippage and uneven load distribution caused extra wear on crane trolleys and hoist wires.

- Solution implemented: Adjustable clamps with self-aligning jaw mechanisms and stronger gripping teeth were introduced.

- Outcome: Handling of irregular billets became safe and predictable, reducing accidents and crane maintenance requirements.

Lesson learned: When billet shapes are inconsistent, clamps with self-aligning features or jaw flexibility are critical to maintain stability, safety, and equipment longevity.

Key Takeaways for Buyers

- Always match clamp design to the most common and extreme billet sizes in your operations.

- Adjustable or customized clamps may cost more upfront but often save money in reduced downtime, maintenance, and scrap.

- Consider billet temperature, length, and shape when selecting clamps for optimal crane performance.

Conclusion

Billet size variations play a critical role in every aspect of crane and clamp selection. From the smallest 100×100 mm billets to oversized 180×180 mm or long 12-meter pieces, differences in width, height, length, and surface condition influence clamp design, crane stability, and operational costs. Choosing the wrong clamp can lead to slippage, material damage, uneven load distribution, and accelerated wear on cranes and trolleys.

Proper clamp selection also affects pricing. While standard clamps may seem cheaper initially, workshops handling diverse billet sizes often benefit more from adjustable or customized clamps. These options reduce downtime, minimize maintenance, and improve long-term operational efficiency, offering a higher return on investment.

Key Takeaways for Buyers:

- Prioritize Safety: Select clamps that securely grip billets of all sizes and shapes, with features like safety locks, overload protection, and heat-resistant materials for hot billets.

- Focus on Adaptability: Adjustable or multi-purpose clamps handle size variations, twisted billets, and rectangular or irregular shapes, reducing the need for multiple fixed clamps.

- Balance Cost-Effectiveness: Consider both upfront purchase costs and long-term operational savings. Investing in the right clamps can reduce maintenance, downtime, and material damage, ultimately lowering total cost of ownership.

- Plan for Crane Compatibility: Ensure that clamp choice aligns with crane capacity, jaw opening, clamping force, and runway design to maintain stability and prevent equipment wear.

By carefully evaluating billet size variations, clamp flexibility, and operational conditions, buyers can make informed decisions that improve safety, efficiency, and cost-effectiveness across steel handling operations.